Peanut Digger-Shaker-Inverter (DSI)

go.ncsu.edu/readext?822557

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

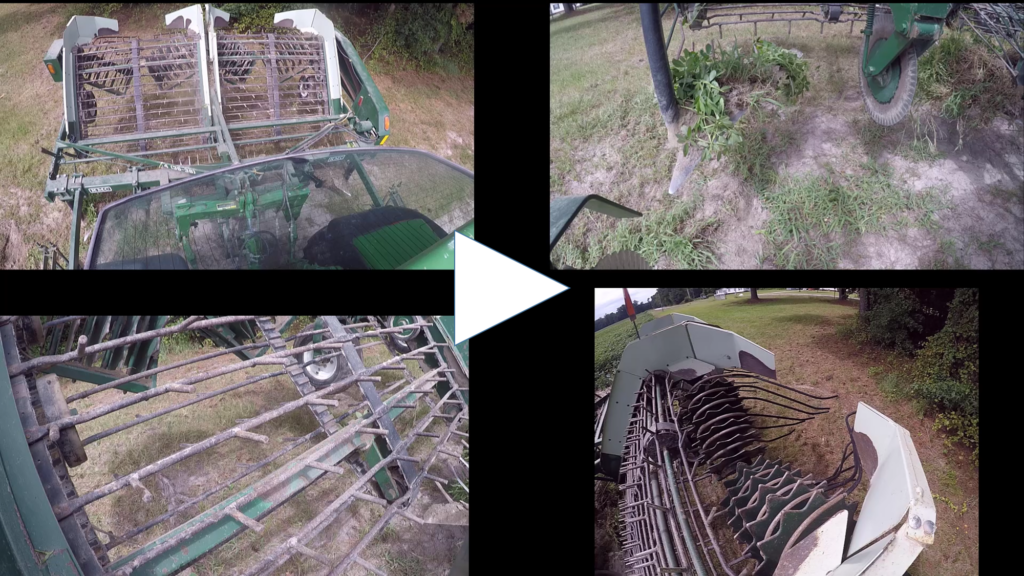

Collapse ▲Peanut Digger-Shaker-Inverter Optimization

Gary Roberson and Jason Ward

Extension Specialists

Biological and Agricultural Engineering

North Carolina State University

Well before reaching a decision on what date to begin harvesting peanuts, careful consideration should be given to preparing the harvest machines. Like most machines, the peanut digger-shaker-inverter (DSI), or just digger for short, performs best when well maintained and properly prepared for the harvest season. Once in the field, attention should turn to proper operating practices, including good daily maintenance.

Field operation and adjustment of the digger-shaker-inverter will be the focus of this guide. Each process needs to perform well so that the entire digging process can be successful. Let’s look at each function, some key adjustments, and how to diagnose if something needs to be changed.

The peanut DSI, as its name implies has three key functions:

- dig peanuts from the ground,

- shake dirt from the peanuts, and

- invert the peanuts into a windrow for field curing.

To accomplish these tasks effectively, the operator should focus on a few key points: digging depth, blade quality, speed and synchronization, shaker action, and inversion.

Digging Depth

Digging is the responsibility of the blades, but depth control actually begins with the gauge wheel or support wheel at the back of the DSI. This wheel position should be adjusted as indicated in the Operator Manual for the target digging depth. This setting may vary depending on planting parameters such as height of bed or if the peanuts were planted on flat ground.

The key takeaways of depth adjustment, for a three-point hitch DSI implement, is to turn off draft control and to not have the implement weight supported by the lift arms on the tractor. The machine should rest on the gauge wheels, per the manual, and then the hydraulic top-link fine tunes depth based on blade angle. Pull-type diggers have essentially the same adjustments.

With the gauge wheel properly set, the tractor hydraulic lift is typically put in position control mode. When the lift is lowered all the way down, the lift arms can float, depth is controlled by adjusting the top link of the three point hitch. Pull type diggers have a similar adjustment.

Blade angle and depth matters because it has a direct impact on the amount and quality of peanuts that are dug and then harvested. A great growing season can be undone by bad digging. Digging too shallow will leave peanuts in the field by cutting them off from the vines or will damage peanuts by cutting them with the blade. Digging too deep can also result in peanuts being left in the field when the vines are lifted.

Below is a slow-motion video of a digger being intentionally moved too shallow and then back to the correct depth. Notice how the vines narrow on the shaker and there does not appear to be any pods on the belt. Then the shaker belt quickly loads with vine and pods when back at depth.

To diagnose cutting depth, look for the roots of recently harvested rows (Figure 3). If there is no measurable root left under the pods then the cutting blade may be too shallow. Roots longer than 2 inches may indicate that the blade is too deep. Consistent roots of about an inch below the pods indicates that the blade is in a good position for digging under your conditions.

Blade Quality

Blades start the harvest process in the field. Blades should be kept sharp so they can slice through the soil and roots cleanly and smoothly. The blade should be nearly flat with a slight lift in the rear, typically ½ inch. Most peanut blades have a smooth side and a beveled side. The beveled side offers more aggressive digging action for harder soils. The smooth side works best in softer soils. Blades with hardened steel edges are also available. These blades promise extended life and the ability to maintain a sharper edge. Check blade condition frequently and replace as soon as they become worn.

Figure 4 shows the leading and trailing edge of a digger blade. While this blade is in good condition, notice the slight curve toward the tip of the blade. Continued wear in the same pattern will lead to blade being replaced. At the rear of the blade are rods that help guide vines onto the shaker belt. The rods do not wear evenly, see that the shortest rod is nearly flat and will need to be monitored to ensure that they are working properly.

Speed and Speed Synchronization

Digger speed has two elements, ground speed and shaker chain speed. Chain speed is set by the tractor PTO on older diggers or by the hydraulic drive on most newer diggers. Ground speed is determined by engine speed and gear selection. Since PTO speed is a function of engine speed, chain speed is set by setting the engine speed as recommended by the digger manufacturer. Engine speed should typically be set to deliver 70% to 90% percent of rated PTO speed. Refer to your tractor manual or speed chart to determine the appropriate setting. Chain speed for hydraulic diggers is controlled by adjusting the hydraulic flow from the tractor or by adjusting the control valve provided on the digger.

Ground speed should be between 2 to 3 MPH initially. Ground speed and chain speed should be nearly matched to ensure good synchronization. To determine how well synchronized your digger is, mark a few sets of adjacent rows with spray paint or surveyors tape. Dig one set of rows and leave the adjacent set undisturbed. Check to see where the peanuts in the row dug fell back to the ground. Ideally they should fall about 1 foot away, and slightly down field (away from tractor travel direction). If ground speed is too slow for the shaker speed, peanuts will land farther down field (away from tractor direction of travel). If ground speed is too fast for the shaker speed, peanuts will land up field (in the direction of travel).

Increasing engine speed will increase both chain and ground speed for PTO powered diggers. Changing gears at the same engine RPM will change ground speed while keeping chain speed constant. For a hydraulic drive digger, chain speed is independent of engine speed or ground speed, as long as the hydraulic system is delivering the required flow rate.

Chain speed indicators are available on many digger models. These indicators will read the chain speed and display the speed in MPH. You can use this feature to accurately adjust chain speed to synchronize chain speed with ground speed.

Shaking Action

Shaking is the process of removing dirt from the vines. Shaking aggression is controlled by positioning the knocker wheels under the chain or belt. The more they are engaged, the more the belt will shake. Too much agitation can shake off peanuts, too little leaves more dirt attached for the combine to manage. Use just enough action to remove dirt, not peanuts.

Inverting is the section of the implement that turns the vines over to begin the windrow curing process. Peanut vines should be fully inverted so the peanuts are exposed to wind and sun and rest on the vines. Full inversion ensures good drying and curing in the window. The inverter rods should be adjusted to the pattern indicated in the operator manual. This provides a good starting point. You can adjust the position slightly to improve the inversion if you see the flow of peanuts through the inverter is not as smooth as needed. Quality of the windrow can also depend on the condition of the vines as they are dug

Summary

Digging sets the stage for harvest success. While running the DSI, stopping to observe the crops and make adjustments will improve harvest efficiency and put more peanuts in the hopper.